By Navin Singh & Rahul Babar

INTRODUCTION India is a fast developing economy and has recently gained prominence in the world as a global leader. There is a huge pool of scientists, engineers and doctors available in the country which is contributing to the fast pace of development on all fronts. The government has taken good measures to raise the standard of living of the citizens by focusing on infrastructure development. But, due to the huge population, rapid industrialisation and fast urbanization, there are major challenges to be overcome. The sanitation sector was neglected during the earlier decades after independence. This led to widespread pollution due to improper disposal of solid and liquid wastes. Till 2014, the sanitation coverage of India was only 39%. There was no toilet facility for 55 crore people before 2014. More than 10 crore toilets were constructed under Swachh Bharat Mission phase I. A massive campaign under the Prime Minister’s leadership was launched to bring about behavioural change in people to use the toilets. By the year 2019, India had achieved more than 99% sanitation coverage. The government has begun the implementation of phase II of Swachh Bharat Mission in the year 2020. The focus of SBM (Gramin) shall be on overall cleanliness in villages through solid and liquid waste management and the sustainability of abolition of open defecation.

THE CHALLENGE For liquid waste management, there are many wastewater treatment technologies in the market. But, the conventional systems (like Activated Sludge Process, MBBR, SBR etc.) are energy intensive and require skilled manpower, thereby, incurring high operation and maintenance costs. Natural systems offer a better alternative to these systems and are being implemented worldwide especially in warm climate regions. As the water scarcity is increasing day by day, it has become important to preserve the existing water sources. Hence, wastewater treatment has to be taken up on priority to avoid pollution of the existing water sources and further aggravation of the water shortage problem. The treated water can be reused for gardening, irrigation, construction, toilet flushing etc. thereby saving on drinking quality water. Proper wastewater treatment not only makes ecological sense but also economical one. The sources of sewage generation are residential areas, industries and institutions. For municipal sewage, the Activated sludge process (ASP) is the most commonly adopted treatment technology in Class I cities covering 59.5% of total installed capacity. The conventional methods in use based on Activated Sludge Process (such as extended aeration, ASP, SAFF, MBBR, FAB, etc.,) are generally energy intensive and require skilled manpower. These systems have high capital costs and are expensive to operate. These STPs (especially de-centralised and small capacity ones) are usually run by unskilled people without any technical back-up. Thereby, the dayto-day variation in performance is not evaluated at most of the STPs. This results in poor performance of these systems leading to their failure. Hence, there is a need to identify energy efficient wastewater treatment systems which require less skill and which are suitable for Indian conditions. Generally, the sewage in towns and cities is transported to one end of the city and then treated. Thus, there is heavy expenditure incurred for conveyance of sewage involving huge pipelines and more pumping stations. There is a need to set up STPs in decentralized manner to reduce the conveyance costs and also reuse the treated water in the same areas from where the sewage is collected. THE SOLUTION Proper selection of technologies is necessary to tackle such ahuge task of sewage treatment on a national level. The conventional treatment systems may be unavoidable in our existing towns mainly owing to land constraint. There are many technologies like MBBR, SBR, up-flow anaerobic sludge blanket reactor (UASB), rotating biological contactors (RBC) for conventional treatment. But, considering the energy crisis, wherever possible, it will be beneficial to adopt natural treatment systems such as Solid Immobilised Bio-Filter (SIBF) system, waste stabilization ponds, oxidation ponds, root zone systems, etc. The SIBF system is a proven and sustainable natural wastewater treatment system. This is best suited for de-centralised STPs. In cities, SIBF systems of smaller capacities can be set up in institutions, townships and / or at ward level in each city. These can be located in big parks / gardens in cities. The treated water from the systems can be reused for maintaining greenery in these parks and also for non-potable uses like construction, landscaping in the nearby areas. They shall also act as additional carbon sinks. In villages, one or two STPs may be installed and the treated water (available throughout the year) can be used for irrigation. Government of Maharashtra has issued the regulations Govt. Of Maharashtra – Urban Development Department (2020) (UDCPR-2020) for mandatory recycling of grey water in housing societies with more than 100 flats and / or area above 10,000 sq.m. The treated water is to be used for non-potable uses like gardening, toilet flushing, car washing, irrigation, etc. SIBF system can be adopted for such residential areas. ABOUT SIBF SYSTEM SIBF system is a natural method of wastewater treatment based on ecological engineering. The treatment is achieved through the ecosystem developed for the specific requirement. There is about 95% recovery of the wastewater as treated water. The treatment cost works out to about Rs. 7/- per 1,000 litres of wastewater treated. Area requirement of SIBF system is about 3.5sq.m. per cu. m. of sewage. This works out to about 0.5 sq.m. per person. Batchelor and Loots (1995) has given the area requirement for treating domestic sewage in constructed wetlands as per European literature of 2 to 5 sq.m. per person. Arceivala and Asolekar (2005) have mentioned area requirement of 1 to 2 sq.m. per person for Indian conditions. SIBF System is entirely different from conventional STPs/ETPs & other similar looking naturalmethods such as Root zone/ Reed bed system, Dewats, Phytorid, SBT, Ecosan, etc.We are in the process of converting some of these into our SIBF System.There are more than 70 SIBF installations ranging from meat processing waste water to hospital / residential / ashram / institutional / industrial waste water.

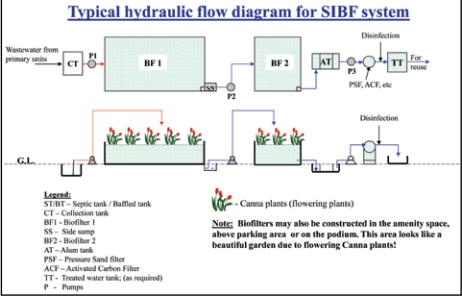

The salient features of the SIBF system are: v Eco-friendly treatment system – Eliminates drawbacks of conventional STP v Landscaping – The total STP looks like a beautiful garden, thus adds to landscaping. v Capital cost¬- Less than conventional treatment systems v Tax benefit – 100% depreciation benefit v Energy conserving – Saves 80 – 90% of energy costs over conventional treatment methods v Easy to operate – Requires very low operating skill v Very low operating cost –Attributed to low energy and low skill requirement v Provides value-addition – Re-usable treated water at very low operational cost, hence, a practicable approach towards groundwater recharge by using the treated water for gardening / irrigation throughout the year. THE PROCESS: Figure showing the typical hydraulic flow diagram of SIBF system The wastewater is treated through a threestage process (refer flow diagram above). 1. Primary treatment: Depending on the type of wastewater, this treatment involves screening, oil / fat removal, equalization, etc. After this, the wastewater is collected in the collection tank. 2. Secondary treatment: From the collection tank, the wastewater is pumped to biofilter 1. This wastewater is spread evenly on the entire biofilter area by piping & distribution network. The wastewater flows vertically downwards through the ecosystem layer of aerobic bacteria – plants in the biofilter. The impurities in the wastewater are trapped and stabilized in this layer. The water from biofilter 1 is collected and pumped into biofilter 2 for second stage biofiltration. 3. Tertiary treatment: The treated water after two stage biofiltration is given tertiary treatment for polishing. This water is passed through alum tank followed by pressure sand filter and activated carbon filter. Finally, the treated water is disinfected and reused. CASE STUDIES Two case studies of the SIBF system installations are given as examples of decentralised sewage treatment and reuse. Case study I: SIBF system at a Residential School SIBF system (Phase I) of 40,000 litres per day capacity has been set up at J. Krishnamurti Foundation’s Sahyadri School near Rajgurunagar in Pune district. The school campus is on the periphery of a dam reservoir. Hence, proper wastewater treatment was necessary to avoid pollution of the reservoir. After proper evaluation of different natural and conventional systems, the management adopted SIBF system. Presently, the treated water is being reused for organic farming and landscaping in the premises.Phase II of 60,000 litres per day capacity is also planned in the near future. The graph below gives the performance of the system (BOD, COD and TSS).

Case study II: SIBF system at an Apartment / township SIBF system of 30,000 litres per day capacity has been set up at Nandanvanapartmentof 48 flats built by Swagat Builders in Pune. The treated water is being reused for toilet flushing and gardening. Due to reuse of the treated water, there is about 50% reduction in fresh water requirement.The biofilters have been set up along the boundary wall next to the driveway. Biofilters may also be constructed above the parking area or on the podium. A STP of 500 KLD has been planned for a township in Pune district for a 1000 flat township. SIBF system for Phase I has been installed.